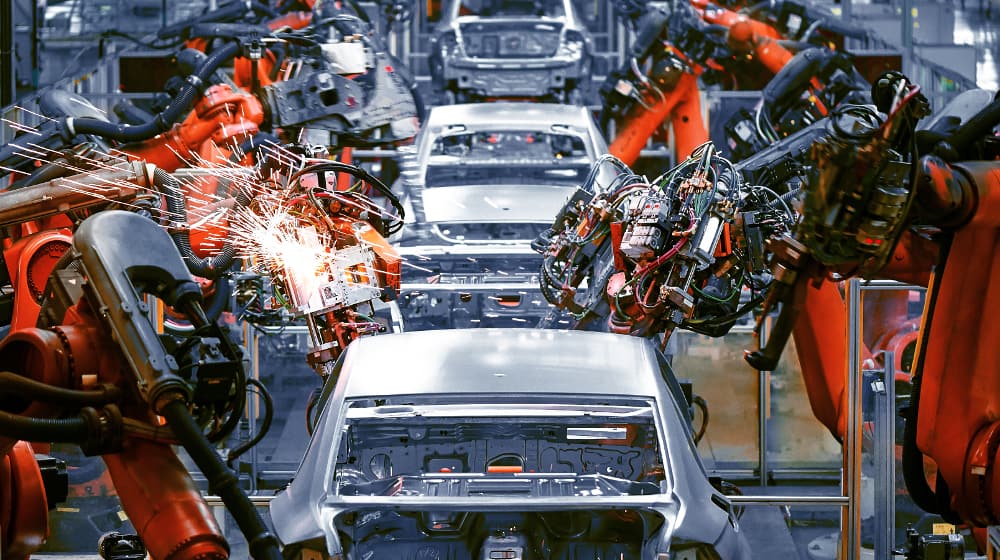

In the fast-paced world of vehicle manufacturing, the quality of automotive test equipment plays a critical role in ensuring the functionality, safety, and performance of automobiles. From conducting rigorous stress tests to identifying potential defects during the production process, automotive test equipment is the bedrock of quality assurance in the automotive industry.

Without the precision and reliability of these testing tools, manufacturers would struggle to meet the high standards demanded by consumers and regulatory bodies alike. In this article, we delve into the indispensable role that automotive test equipment plays in revving up the quality of vehicles on the road today.

Importance of Quality Control in Vehicle Manufacturing

Quality control in vehicle manufacturing is crucial for ensuring that the final product meets the high standards expected by consumers. Implementing rigorous quality control processes helps to prevent defects, minimize rework, and ultimately save time and money in the manufacturing process.

By detecting and addressing issues early on, manufacturers can avoid costly recalls and reputation damage. Quality control also plays a key role in enhancing customer satisfaction and loyalty, as it ensures that vehicles are safe, reliable, and perform optimally.

Without proper quality control measures in place, the risk of defective products reaching the market is significantly higher, leading to potential safety hazards and negative impacts on the brand’s reputation. Automotive manufacturers need to invest in quality control tools and equipment to uphold the highest standards of safety and quality in vehicle production.

Key Functions and Features of Automotive Test Equipment

The automotive test equipment used in vehicle manufacturing plays a critical role in ensuring the quality and reliability of automobiles. These essential tools serve various key functions and offer a range of features that help automotive professionals diagnose, troubleshoot, and fine-tune vehicles during the production process.

Some of the key functions of automotive test equipment include checking the performance of electrical systems, evaluating engine efficiency, measuring emissions, testing suspension components, and verifying overall vehicle safety. Additionally, modern automotive test equipment is equipped with advanced features such as real-time data monitoring, wireless connectivity, user-friendly interfaces, and diagnostic capabilities that provide valuable insights for improving vehicle performance and meeting industry standards.

By utilizing these innovative tools, automotive manufacturers can uphold high-quality standards, boost efficiency, and deliver safe and reliable vehicles to consumers worldwide.

Types of Test Equipment Used in Vehicle Manufacturing

The manufacturing of vehicles requires a wide array of specialized test equipment to ensure quality and safety standards are met. Some of the key types of test equipment used in vehicle manufacturing include dynamometers, chassis dynamometers, emissions testing equipment, powertrain testing equipment, and vehicle simulation tools.

Dynamometers are used to measure the torque, horsepower, and emissions of engines, while chassis dynamometers simulate real-world driving conditions to test vehicle performance. Emissions testing equipment is essential for ensuring vehicles comply with environmental regulations, while powertrain testing equipment is used to evaluate the performance and durability of the vehicle’s powertrain components.

Vehicle simulation tools allow manufacturers to test various scenarios and conditions without needing physical prototypes, saving time and resources in the development process. Each type of test equipment plays a crucial role in the quality control and innovation of vehicles in the automotive industry.

Impact of Test Equipment on Product Quality and Safety

The impact of test equipment on product quality and safety in automotive manufacturing cannot be overstated. By using cutting-edge testing tools and technologies, manufacturers can ensure that every vehicle that rolls off the assembly line meets the highest quality and safety standards. From testing engines and airbags to ensuring proper alignment and functioning of various electronic components, automotive test equipment plays a crucial role in not only improving the overall performance of vehicles but also in enhancing the safety of drivers and passengers.

With the constant evolution of technology, manufacturers must stay ahead of the curve by investing in advanced test equipment that can keep up with the demands of the ever-changing automotive industry.

Best Practices for Implementing Automotive Test Equipment in Manufacturing Processes

To effectively implement automotive test equipment in manufacturing processes, several best practices can be followed to ensure optimal performance and quality control. First and foremost, it is essential to conduct thorough training for workers who will be using the test equipment to ensure proper utilization and interpretation of results.

Additionally, regular maintenance and calibration of the equipment are crucial to guarantee accurate and reliable testing. It is also important to establish clear guidelines and protocols for conducting tests to ensure consistency and repeatability.

Regular audits and reviews of testing processes can help identify any potential issues or areas for improvement. By following these best practices, automotive manufacturers can enhance their production processes and ultimately improve the quality of their vehicles.

Future Trends and Innovations in Automotive Test Equipment

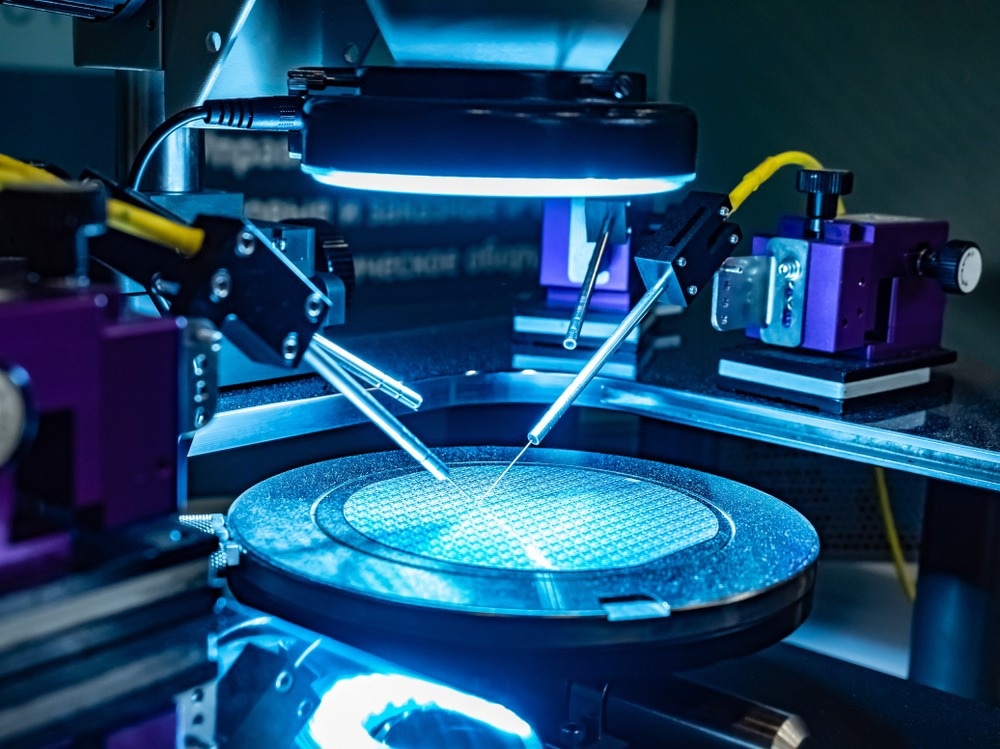

The automotive industry is constantly evolving, with new technologies and innovations reshaping the way vehicles are designed and manufactured. As consumer demands change and environmental regulations become more stringent, automotive test equipment must also adapt to meet these evolving needs.

From advanced diagnostic tools to cutting-edge simulation software, the future of automotive test equipment is marked by increased precision, efficiency, and connectivity. Manufacturers are investing in 3D printing and virtual reality technologies to streamline testing processes and reduce time-to-market.

Additionally, the integration of artificial intelligence and machine learning algorithms is revolutionizing how data is collected, analyzed, and utilized in vehicle testing. As the automotive industry continues to push the boundaries of innovation, the role of test equipment in ensuring the quality and safety of vehicles will be more critical than ever.

Conclusion

In conclusion, automotive test equipment plays a crucial role in ensuring the quality and safety of vehicles produced in the automotive industry. By utilizing advanced testing technologies and equipment, manufacturers can identify and address potential issues early in the production process, ultimately leading to higher-quality vehicles that meet industry standards and exceed customer expectations.

Investing in reliable automotive test equipment is not only essential for maintaining a competitive edge in the market but also for prioritizing consumer safety and satisfaction. As technology continues to evolve, the importance of high-quality automotive test equipment will only continue to grow in the ever-changing landscape of vehicle manufacturing.